How to avoid the quality problem of steel core aluminum stranded wire of overhead insulated conductor

Release time:

2021-07-19

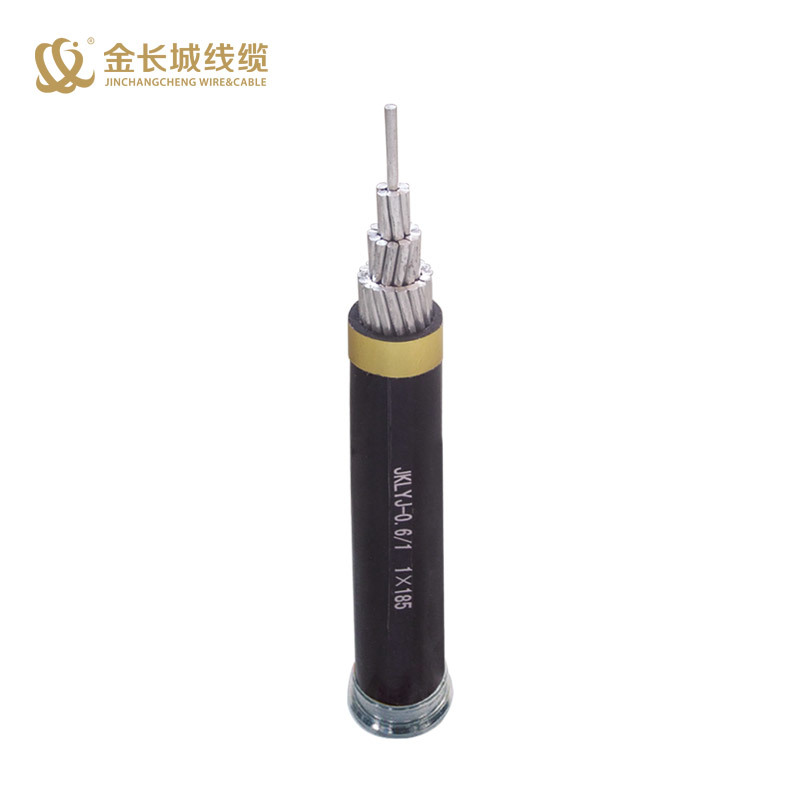

In the production and processing process of the steel core aluminum stranded wire of the overhead insulated wire, if the method is improper or the operation is improper, quality problems are prone to occur, resulting in unqualified performance of the finished product. Not working properly.

Inoverhead insulated conductorIn the production and processing of ACSR, if the method is improper or the operation is improper, it is easy to have quality problems, resulting in unqualified performance of the finished product. Not working properly. In general, a single cable break is caused by a single wire winding too tight or too loose, resulting in the cable being stuck or twisted. This situation, such as in the wiring process to check in time to ensure that the winding level can be avoided. If the threading pipe has severe wear or tension, it is easy to check and solve.

In the production process of the steel core aluminum stranded wire of the overhead insulated conductor, the appropriate parameters such as the middle diameter ratio and the stranding rate should be set before the start-up to ensure that the performance of the produced cable meets the design requirements. In addition, in the stranding process, we should try to be in place at one time to avoid frequent shutdowns and starts, so as to better ensure uniform production and avoid single-line arching and loosening.

Attention should also be paid to the finished or semi-finished products of ACSR in the processing workshop. They should be properly placed and protected to avoid physical damage to the appearance caused by collision, thereby affecting performance.

Aluminum-clad steel core aluminum stranded wire manufacturersTo tell you, several reasons for the aging of overhead insulated conductor cables are as follows:

1. Causes of cable aging: external force damage. According to the operation analysis in recent years, especially in Haipu District, a large number of cable failures are caused by mechanical damage. If the damage is not serious, it will take months or even years to cause the damaged parts to completely collapse and form a failure.

2. Causes of cable aging: insulation is damp. This situation is also very common, generally occurred in the cable joints buried or pipe. For example, if the cable joint does not meet the standards or is manufactured in a humid climate, the joint will be filled with water or mixed with water vapor.

3. Causes of cable aging: chemical corrosion. When the cable is directly buried in the acid-base area, the armor, lead skin or outer protective layer of the cable will be corroded. Due to the long-term chemical or electrolytic corrosion of the protective layer, the protective layer fails, the insulation performance is reduced, and the cable failure is also caused.

4. Causes of cable aging: long-term overload operation. During overload operation, due to the thermal effect of the current, the load current through the cable will inevitably lead to heating of the conductor, at the same time, the skin effect of the charge, the eddy current loss of the steel armor and the media loss will also generate additional heat, so that the cable temperature increases. During long-term overload operation, excessive temperature will accelerate insulation aging and cause insulation breakdown. Especially in the hot summer, the temperature rise of the cable often leads to the first breakdown of the weak part of the cable insulation, so in the summer, cable failures occur from time to time.

5. Causes of cable aging: cable joint failure. The cable joint is the weakest link in the cable line, and the cable joint failure caused by the direct negligence of the personnel occurs from time to time. In the process of making cable joints, if the original network such as loose crimping and insufficient heat generation occurs, the insulation of the cable head will be reduced, resulting in accidents.

Causes of cable aging: environment and temperature. The external environment and heat source of the cable will also cause the cable temperature to be too high, insulation breakdown, and even explosion and fire.

Want to know moreAluminum-clad steel-core aluminum stranded wire, steel-core aluminum stranded wireThe content, can pay attention to us.

TAG:

Recommend

Service Hotline:

E-mail:

Address:

Yincun Economic Development Zone, Renqiu City, Cangzhou City, Hebei Province