Reasons for the manufacture of high-voltage cables

Release time:

2021-08-03

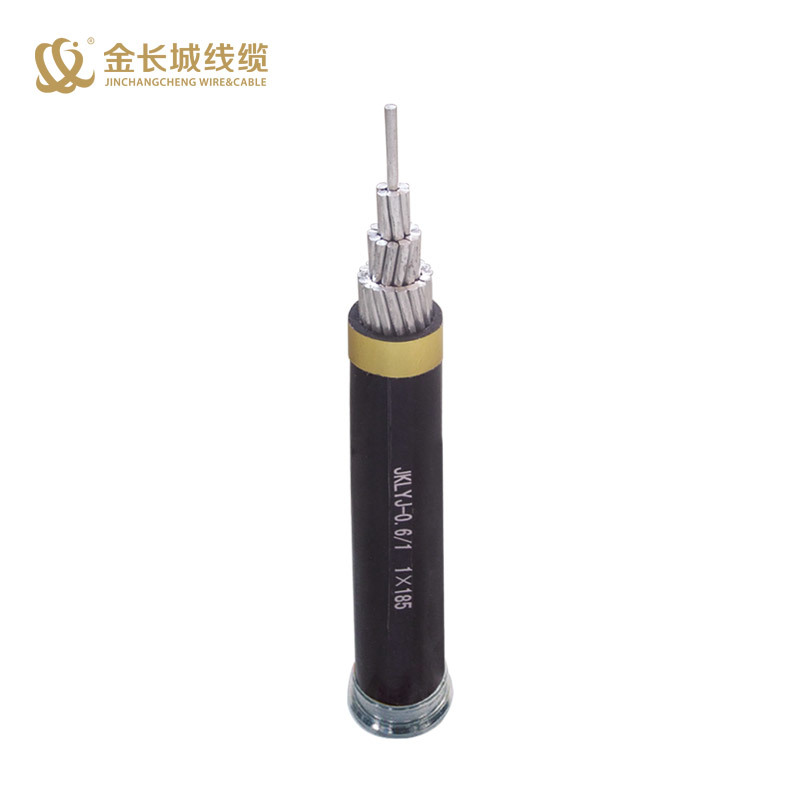

High-voltage cable is a kind of power cable, which is used to transmit power cables between 1 kV and 1000 kV, and is mostly used for transmission and distribution. Due to the excellent conductivity of copper conductors, more and more projects use copper-core power cables as the main road of the power supply system, while aluminum-core power cables are used less, especially in power systems with higher voltages, the more copper-core cables are used. The high-voltage cable consists of the conductor, insulation, inner sheath, filler (armor) and outer insulation. Of course, armored high-voltage cables are mainly used for underground burial, which can resist high-strength compression on the ground and prevent other external forces from destroying.

High voltage cableIt is a kind of power cable, which is used to transmit power cables between 1 kV and 1000 kV, and is mostly used for transmission and distribution. Due to the excellent conductivity of copper conductors, more and more projects use copper-core power cables as the main road of the power supply system, while aluminum-core power cables are used less, especially in power systems with higher voltages, the more copper-core cables are used. The high-voltage cable consists of the conductor, insulation, inner sheath, filler (armor) and outer insulation. Of course, armored high-voltage cables are mainly used for underground burial, which can resist high-strength compression on the ground and prevent other external forces from destroying.

High-voltage cables are used for fixed transmission and distribution lines with AC rated voltage of 35KV and below. The maximum long-term working temperature of the cable conductor is 90 ℃, and the maximum temperature of the cable conductor does not exceed 250 ℃ when a short circuit occurs (the longest time does not exceed 5S). UHV cable is a kind of power cable with the continuous development of cable technology. As the central link of large-scale transmission system, UHV cable is a kind of high-voltage cable with high technical content, which is mainly used for long-distance transmission.

Cable is a bridge connecting power supply equipment and electrical equipment, and plays a role in transmitting electric energy. It is widely used, so failures often occur. The following is a brief analysis of the causes of common problems with high-voltage cables. According to the cause of the failure can be roughly divided into the following categories: manufacturers manufacturing reasons, construction quality reasons, design unit design reasons, external force damage.Power cable manufacturers, national grid bidding cable manufacturers.Explain for everyone.

The manufacturer's manufacturing reasons can be divided into three categories according to different locations: cable body reasons, cable joint reasons, cable grounding system reasons.

Reasons for cable body manufacturing: The problems that are prone to occur in the general cable production process include insulation eccentricity, uneven thickness of insulation shielding layer, impurities in insulation, prominent internal and external shielding layer, uneven crosslinking, cable moisture, and poor sealing of cable metal sheath. In some cases, the failure may occur during the completion test or shortly after commissioning, most of which exist in the form of cable system defects, causing serious hidden dangers to the long-term safe operation of the cable.

The reason for the manufacture of cable joints: In the past, high-voltage cable joints were all wound and molded, requiring a large number of on-site production. Due to the limitations of field conditions and manufacturing processes, there are inevitably air gaps and impurities between insulating tapes, which are prone to problems. The types commonly used in China are assembly type and assembly type. Cable joints are divided into cable terminal joints and cable intermediate joints. Regardless of the joint form, cable joint failure usually occurs where the cable insulation screen breaks, because this is where the electrical stress is concentrated. The causes of cable joint failure due to manufacturing reasons include stress cone manufacturing defects, insulating packing problems, sealing ring oil leakage, etc.

Cable grounding system: cable grounding system includes cable grounding box, cable grounding protection box (with sheath protector), cable cross interconnection box, sheath protector, etc. Generally, the main problem that is prone to occur is that the casing is not well sealed, resulting in multi-point grounding and excessive induced current in the metal sheath. In addition, the parameter selection is unreasonable or the quality of the protective layer protector is poor, and the zinc oxide crystal is unstable, which can easily cause damage to the protective layer protector.

TAG:

Recommend

Service Hotline:

E-mail:

Address:

Yincun Economic Development Zone, Renqiu City, Cangzhou City, Hebei Province