Introduction of Structure and Function of Steel-core Aluminum Strand

Release time:

2022-07-05

What is the difference between the division of labor of steel core aluminum stranded wire synthetic products? First of all, the strength of the steel core is very high, so it is used to increase the strength of the steel wire. Aluminum wire, as we all know, is the aluminum wire in the household wire, the conductive performance is excellent, so the aluminum stranded wire is used to transmit electric energy.

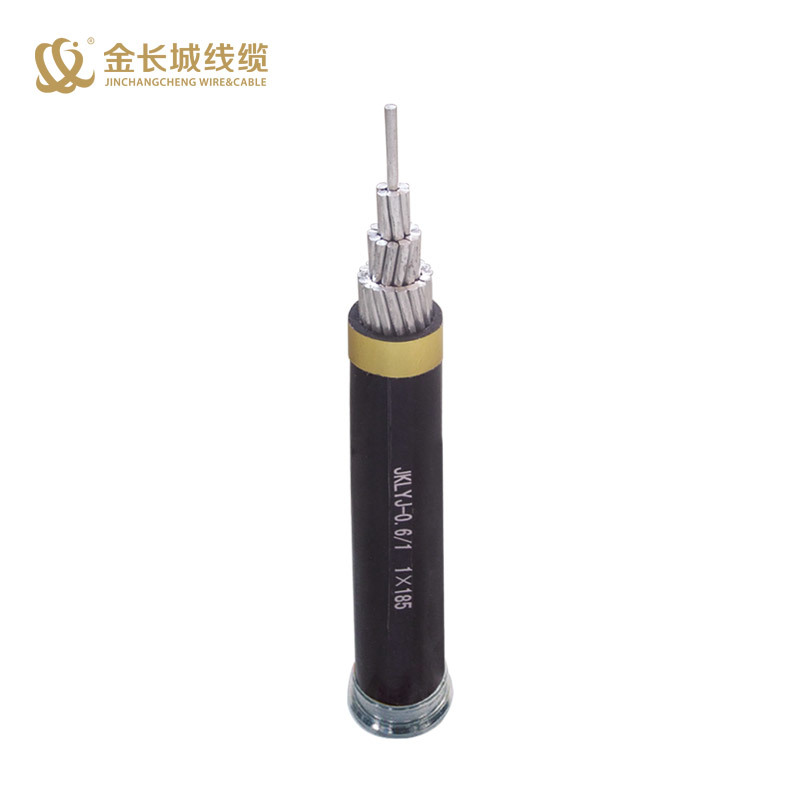

Some people don't know much about ACSR. Mainly used in the power industry and transmission lines. The material can be known from the literal meaning of the steel core aluminum stranded wire, which is a composite of aluminum wire and steel wire. Its inside is mainly steel core, and the outside is aluminum wire, which is coiled with aluminum wire.

What is the difference between the division of labor of steel core aluminum stranded wire synthetic products? First of all, the strength of the steel core is very high, so it is used to increase the strength of the steel wire. Aluminum wire, as we all know, is the aluminum wire in household wire, which has good conductivity, so aluminum stranded wire is used to transmit electric energy.

In general, the structure of the composite steel core aluminum strand is very simple, and it is very convenient to use and protect. The cost of this steel-reinforced aluminum stranded wire is also very low, but the quality is very reliable. Therefore, it has been recognized and affirmed by many users. It is a common line in shopping malls, and the scale of application is also increasing.

Steel core aluminum stranded wire is now a better power cable. Domestic production of this kind of cable talent has been given, the use of domestic ACSR planning is also increasing. The question of confusing the quality of ACSR has been broken by domestic manufacturers, and the first development direction in the next stage is to discuss the independent intellectual property rights of ACSR and explore the environmental protection function.

As far as today's domestic ACSR is concerned, there are two aspects in selecting its quality characteristics. On the one hand, the higher the production process, technical level and capacity, the better the quality of the steel core aluminum strand.

The second aspect is mainly about the raw material of the steel core aluminum strand. Without qualified raw materials, it is the same as "a clever woman cannot cook without rice", so this aspect is also the basic element of the quality of ACSR. Therefore, in order to ensure the quality, it is also necessary to ensure that the raw material environment in the production line also has quality and quality assurance, and continuously supply excellent steel wire and aluminum wire materials for ACSR.

In the production and processing process of ACSR, if the method is wrong or the operation is improper, it is easy to have quality problems, resulting in unqualified use function of the finished product. It cannot be used normally. Cable single-wire cracking is generally due to single-wire too tight or too loose, resulting in being stuck or knotted, and then torn off. If the flat cable can be checked in time during the processing to ensure its smooth winding, this situation can be avoided. However, if the threading pipe is severely worn or the tension is different, it is easy to check and solve.

In the production of steel core aluminum stranded wire, it is necessary to set appropriate parameters before starting the processing, such as pitch diameter ratio, stranding rate, etc., to ensure that the manufactured cable has the function of meeting the requirements of the scheme. In addition, in the process of twisting, try to strike while the iron is hot and avoid frequent downtime, so as to ensure uniform production and avoid single-line bulge and slack.

It should also be noted that it should be properly arranged and protected to avoid physical damage to the appearance caused by bumps, thereby affecting the application function.

TAG:

Previous

Recommend

Service Hotline:

E-mail:

Address:

Yincun Economic Development Zone, Renqiu City, Cangzhou City, Hebei Province