What is the difference between BLX cable and overhead insulated conductor

Release time:

2022-08-12

With the demand of the market, the use of overhead cables is also increasing. Enterprises are producing and developing various overhead insulated conductors required by the market, but there are still customers who require to order BLX cables in daily sales production instead of overhead insulated conductors. At present, most mainstream wire and cable manufacturers no longer produce BLX cables, and the editor puts forward some views on the differences between the two cables.

With the demand of the market, the use of overhead cables is also increasing. Enterprises are producing and developing various overhead insulated conductors required by the market, but there are still customers who require to order BLX cables in daily sales production instead of overhead insulated conductors. At present, most mainstream wire and cable manufacturers no longer produce BLX cables, and the editor puts forward some views on the differences between the two cables.

First, let's take a look at the BLX cable. At present, the production of BLX cable enterprises are mainly based on JB/T1601-1993 "rated voltage 300/500V rubber insulated fixed laying wire". The standard was formulated in 1993. So far, it has not been updated for more than 20 years. The product has gradually been replaced by overhead cables in the market.

BLX type rubber insulated fixed wiring is suitable for electrical equipment and lighting equipment systems with AC rated voltage Uo/U lower than 300/500V. The long-term allowable working temperature of the wire is 65. Its structure is aluminum conductor, rubber insulation extrusion, external weaving silk, fat asphalt material, fat coating asphalt material is anti-ultraviolet. This kind of cable is used for 2 years before and after the wind and sun, the woven glass fiber is stripped and damaged, the life is short, the anti-aging ability is poor, and there are many cases of environmental pollution.

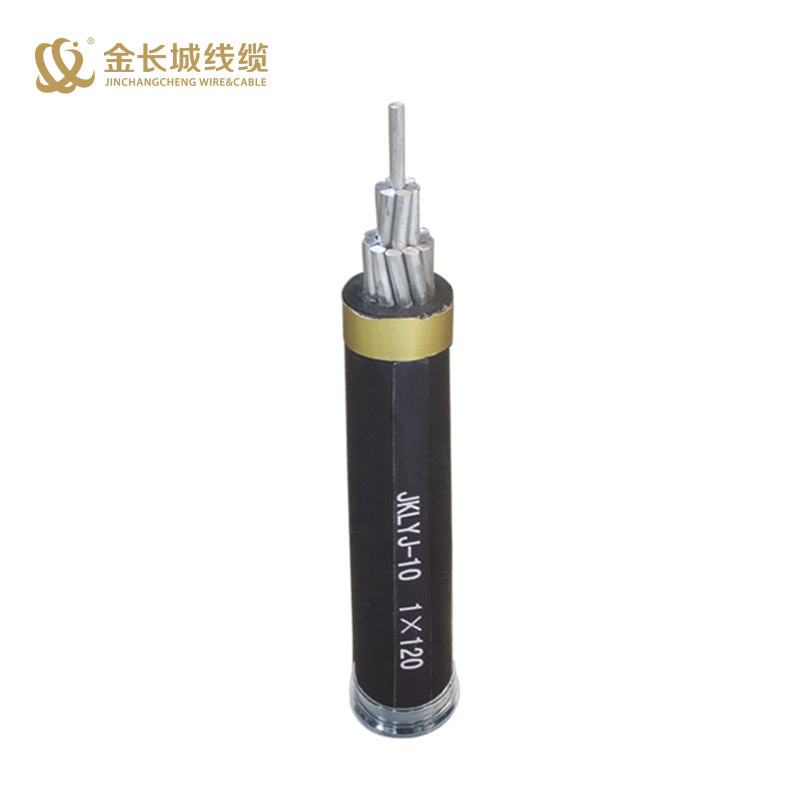

At present, the enterprises producing low-voltage overhead insulated conductors are based on the national standard GB/T12527-2008 "overhead insulated cables with rated voltage of 1kV and below. Overhead insulated wires are mainly used for overhead fixed arrangements, lead wires and other places. The insulation material adopts weather-resistant special overhead insulated cable materials. Therefore, overhead insulated cables have the advantages of simple structure, safety, good mechanical physical and electrical characteristics, and resistance to ultraviolet rays in the environment. Due to the use of weather-resistant special overhead insulated cable materials, the long-term allowable operating temperature of the cable is 70 or 90. The use of overhead insulated cables in routes above m can shorten routing intervals, save circuit corridors, and reduce voltage drops. It can reduce the occurrence of power supply accidents in use.

With the continuous updating of national standards for cable products, according to national electrical safety and reliability requirements, the performance of BLX-type wires is lower than that of overhead cables, so overhead insulated conductors on the market have gradually replaced BLX-type cables.

Main features of overhead insulated conductors

1. Good insulation performance. The newly read overhead insulated cable increases the insulation layer. Because the insulation performance is better than the original wire, the distance between the lines is reduced, the insulation requirements for the circuit support components are reduced, and the number of circuits for the same load installation circuit is increased.

2. Good anti-corrosion performance

Faith Overhead insulated cables have an insulating layer on the outer layer, so compared with exposed wires, the degree of oxidation corrosion is less, the corrosion resistance is stronger, and the life of the line can be extended.

3, to prevent external damage. Faith Overhead insulated cables are affected by external factors such as wood, flying metal films, and dust to reduce interphase short circuits and grounding accidents.

4, to achieve the required strength

Although the newly read overhead insulated cable has less steel core, it is strong and tough, and the mechanical strength of the entire wire can meet the stress design requirements.

TAG:

Recommend

Service Hotline:

E-mail:

Address:

Yincun Economic Development Zone, Renqiu City, Cangzhou City, Hebei Province