What is the difference between aluminum clad steel core aluminum stranded wire and ordinary aluminum stranded wire?

Release time:

2022-11-22

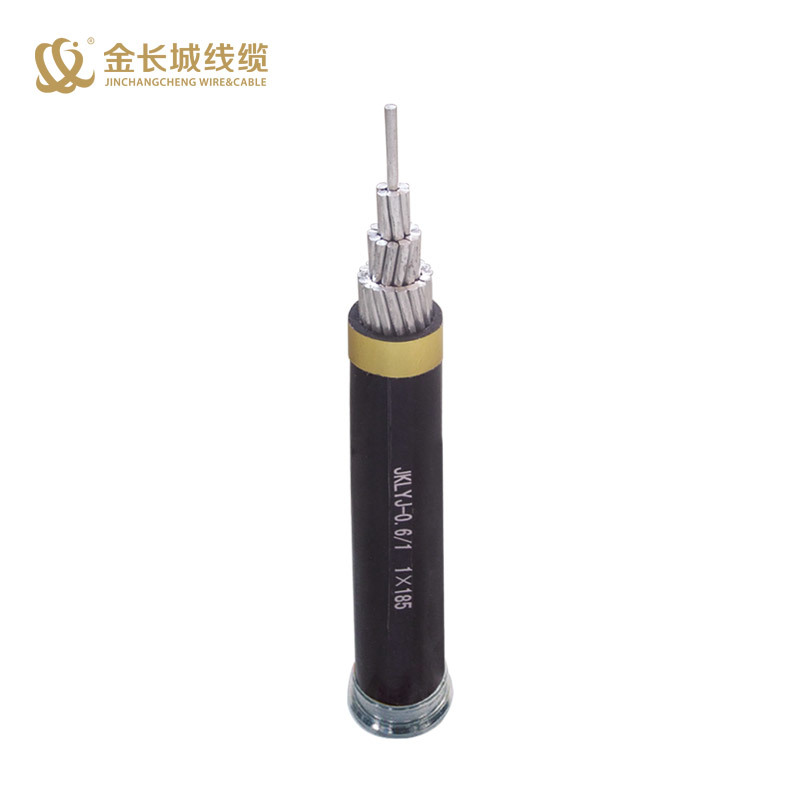

What is the difference between aluminum clad steel core aluminum stranded wire and ordinary aluminum stranded wire? Aluminum-clad steel core aluminum stranded wire refers to the reinforced wire wound with single-layer or multi-layer aluminum stranded wire outside the galvanized steel core wire. It is mainly used in the power and transmission line industry.

What is the difference between aluminum clad steel core aluminum stranded wire and ordinary aluminum stranded wire?

Aluminum-clad steel core aluminum stranded wire refers to the reinforced wire wound with single-layer or multi-layer aluminum stranded wire outside the galvanized steel core wire. It is mainly used in the power and transmission line industry. Its interior is a steel core, and the exterior is twisted and wound on the steel core with aluminum wire; the steel core mainly plays a reinforcing role, and the aluminum stranded wire mainly plays a role in transmitting electric energy. Aluminum-clad steel core aluminum stranded wire has simple structure, convenient installation, convenient maintenance, low line cost, large transmission capacity, good laying across rivers, valleys and other special geographical conditions, good conductivity, sufficient mechanical strength, high tensile strength, and towers Features such as scalable spacing.

Aluminum-clad steel core aluminum stranded wire is a kind of stranded aluminum stranded wire and steel wire, mainly used for overhead transmission lines. The inside of the steel core aluminum stranded wire is a steel "core", and the outside is wrapped around the steel core with aluminum stranded wire; the steel core is mainly used to improve the strength, and the aluminum stranded wire is mainly used to transmit electric energy. Both are bare wires, the use is basically the same, different models and specifications.

Ordinary aluminum stranded wire: the model is indicated by "L J" and belongs to bare wire. At present, aluminum-clad steel strand (LGJ) is widely used as conductor in China. The steel core is mainly used to improve strength, and the aluminum stranded wire is mainly used to transmit electric energy. The cross-sectional area of the wire varies with voltage. For example, LGJ-400/35 conductors are typically used for 500kV transmission lines. L is the abbreviation of aluminum wire, G is the abbreviation of steel core, J is the abbreviation of stranded wire, 400 is aluminum 400 mm2,35 is steel 35mm2.

Model meaning: For example, the nominal cross-section of the GB1179-83 "aluminum stranded wire" is 240 mm2 aluminum stranded wire. Specifications and models can be expressed as: L J-240 GB1179-83GB1179-8.3 "steel core aluminum stranded wire", the nominal cross-section is 300 mm2 aluminum and 50 mm2 steel. Specifications and models can be expressed as: LGJ-300/50 GB1179-93.

Main purpose: Generally speaking, for high-voltage transmission lines, due to the limited line path, it is impossible to set up multiple lines on one path. Therefore, people have proposed a method of using one path, a group of towers, and hanging multiple wires. A line is equivalent to setting up multiple lines. For example, for 500KV transmission lines, China mostly adopts the method of four wire suspension, which is called the method of erecting iron towers at the same time. This is the main reason why some rods are used for "L J" and "LGJ. Welcome to inquire the price of ACSR.

Aluminum clad steel core aluminum stranded wire often faces the problem of cable turning damage: the outer diameter of power cable is large, and it is difficult to transport and lay. Power cable turning radius requirements are also very strict. During the construction of power cables, if the corner is too large, the wires may be mechanically damaged. Cable insulation strength reduces mechanical damage until failure occurs. Cable head failure was found during construction. When making the cable head, the length of the three cable heads is the same. When connecting with the equipment, due to the limitation of terrain, the medium-voltage cable head is too long to arch, and the root of the cable head is damaged and discharged.

Take measures: properly shorten the connection length of the medium voltage cable head in the equipment connection, so that the three-phase cable head is not subject to external force. Practice has proved that the operation effect is good. It can be seen that in the process of cable construction, the torsion of the cable should be reduced as much as possible. When the cable turns and leaves the cable, the cable should bend naturally to prevent internal mechanical damage.

TAG:

Recommend

Service Hotline:

E-mail:

Address:

Yincun Economic Development Zone, Renqiu City, Cangzhou City, Hebei Province