High voltage cable manufacturers: introduction of high voltage cable construction process need to pay attention to matters

Release time:

2023-02-08

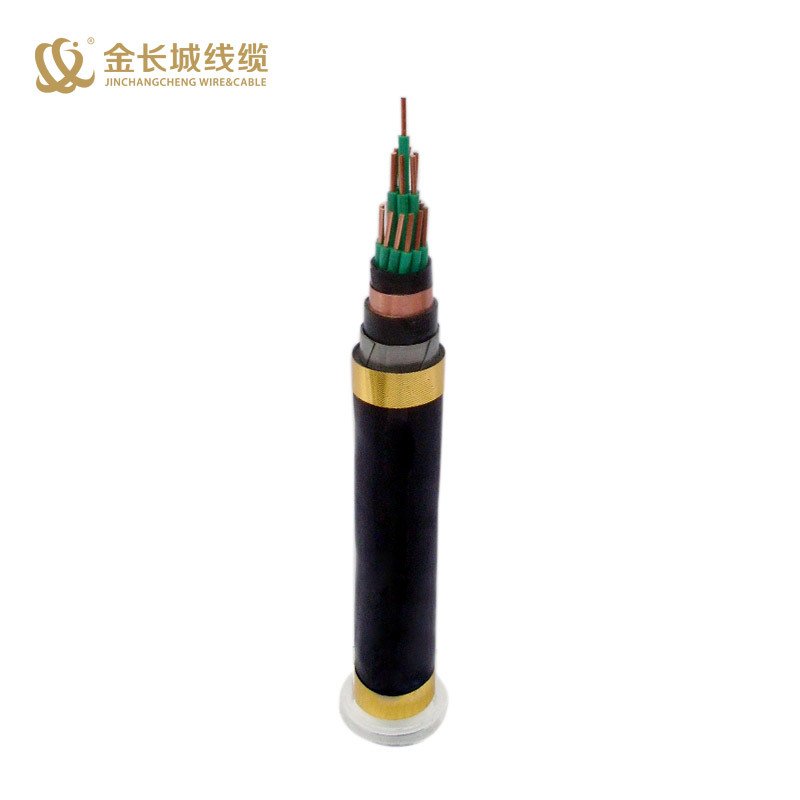

High voltage cable manufacturers: introduction of high voltage cable construction process need to pay attention to matters High-voltage cable model selection is a certain standard, because it is a high-risk raw materials, so in the construction of the project should be more attention. Take a look at the following high voltage cable construction measures.

High voltage cable manufacturers: introduction of high voltage cable construction process need to pay attention to matters

High-voltage cable model selection is a certain standard, because it is a high-risk raw materials, so in the construction of the project should be more attention. Take a look at the following high voltage cable construction measures.

1. Tripod or crane shall be selected for cable loading. It is forbidden to immediately push the road surface violently from the car to prevent the cable shaft from breaking and damaging the cable. When the cable is installed on the car, it is necessary to use a strong rope to fix the cable firmly, and double pad it with inclined wood to prevent injury caused by sudden braking or overturning when driving halfway up and down the slope.

2. When laying the cable, the cable shaft of the support point of the stable and flat road surface shall be selected. The ball screw hydraulic jack support frame used should be easy to rotate. When the cable shaft is raised and lowered, it is necessary to maintain the vertical plane of the port, and the center line of the cable drum must be perpendicular to the plane.

3. After the battery protection plate on the cable shaft is disassembled, the wood boards with nails shall be concentrated and piled to prevent nails from sticking. The remaining nails in the shaft barrel should be properly solved to prevent injuries caused by stabbing hands in the wardrobe.

4. When sawing off the old cable, it is necessary to cut off the power, charge and discharge, electroscope, then ground the cable core, and handle the work permit procedures. The neutral core of the four-core cable shall be removed. Before sawing, it is necessary to compare with the cable engineering drawings. Check whether it is indeed in conformity with the requirements. If conditions permit, the detector shall be applied for certification, and then the cable core shall be nailed with iron rod with wooden handle or wire saw with ground wire before working. The personnel related to the application of iron saws and iron rods shall wear insulating tools and stand on the insulating rubber pad. The copper core wire with a cross section of more than 10mm ² is used for wire connectors, and the grounding device can be driven 0.6 meters below the road surface with garden steel.

5, wiring optical cable cable must be closely organized and have special guidelines, traction belt link should have good contact information. Optical cable wiring end, should check whether the optical fiber line is good. The ends of optical cables shall be sealed and moisture-proof and shall not be soaked.

6, optical cable cable into the pipeline or pipeline turn or cross, should use guide equipment or sound horn cable protection tube, can not damage the optical cable cable outer and outer protection layer, optical cable traction belt length should not exceed 1000 meters, long to choose ∞ word by section traction belt.

7. The optical cable shall be placed on the specified fixed bracket, and a moderate capacity shall be reserved to prevent the optical cable from being too tight. The embedded optical cable in the hole (hand) of the connector shall meet the design points. The embedded optical cable shall be properly placed according to the position.

8. When melting insulating glue, it is necessary to set up full-time personnel to take care of it. The staff should wear linen canvas gloves and shoe covers. Molten insulating glue should try to avoid hand enemy transmission, throw on the ground should pay attention to the right.

9. When the cable head is filled at a high place, there is no need to sit below. Non-motor vehicles are prohibited from entering the operation area. The actual operation site shall be provided with guardrail and special monitoring. The vessel containing molten insulating glue must be tied with a stable rope, and the upper worker should lift it up gradually. Do not bump from east to west. The lower worker should leave far enough to prevent burns. When pouring insulating glue, it should stand at the windward position.

High voltage cable manufacturer: our company has all kinds of cables, welcome to call for advice.

TAG:

Recommend

Service Hotline:

E-mail:

Address:

Yincun Economic Development Zone, Renqiu City, Cangzhou City, Hebei Province