Analysis on Common Problems of High Voltage Cable Manufacturers

Release time:

2022-12-21

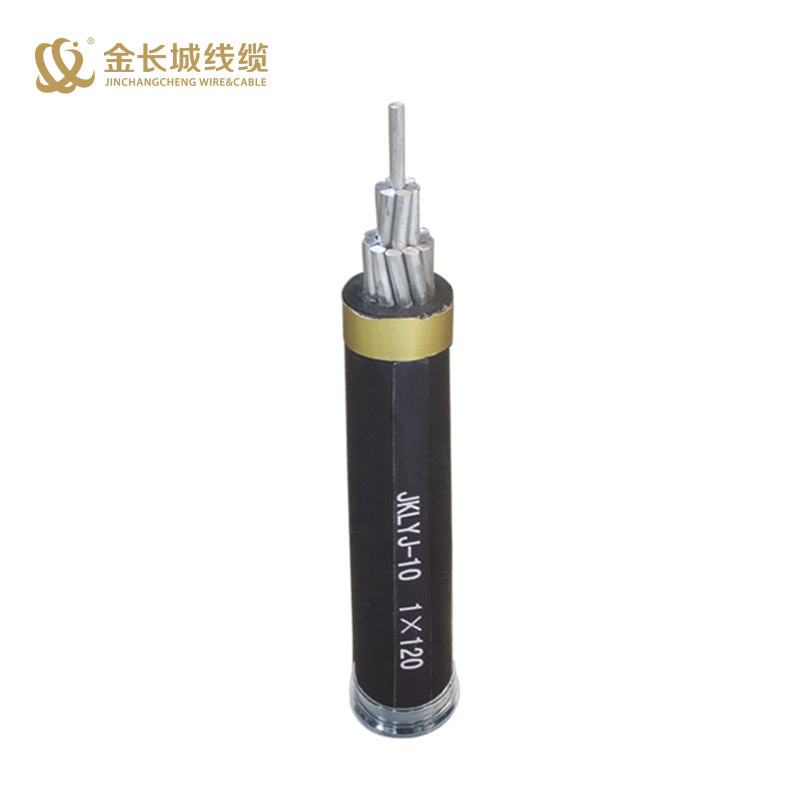

High-voltage cables are used to transmit power between 1kV and 1000kV, and are mostly used for transmission and distribution. The components of a high-voltage cable include, from the inside to the outside: conductor, inner sheath, insulation, filler and outer insulation. Of course, armored high-voltage cables can resist the high-strength pressure of the ground, and are mainly used for underground burial by high-voltage cable manufacturers to prevent other external damage.

High-voltage cables are used to transmit power between 1kV and 1000kV, and are mostly used for transmission and distribution. The components of a high-voltage cable include, from the inside to the outside: conductor, inner sheath, insulation, filler and outer insulation. Of course, armored high-voltage cables can resist the high-strength pressure of the ground, and are mainly used for underground burial by high-voltage cable manufacturers to prevent other external damage.

The cable plays the role of transmitting electric energy and is a bridge between power supply equipment and electrical equipment. It is widely used, so faults often occur. Here high-voltage cable manufacturers briefly analyze the causes of common problems in high-voltage cables, which can be divided into the following categories according to the reasons: manufacturers manufacturing reasons, external force damage, design reasons, etc.

The manufacturing reasons of high-voltage cable manufacturers are divided into three categories according to different parts: cable joint reasons, cable body reasons, and cable grounding system reasons. 1. Reasons for the manufacture of the cable body. Generally speaking, the problems that are prone to occur in the cable production process include uneven thickness of the insulation shielding layer, eccentric insulation, impurities in the insulation, uneven crosslinking, protrusions in the inner and outer shielding layers, moisture in the cable, and poor sealing of the cable metal sheath Wait. Some cases are more serious and may fail soon after the completion test or trial operation, and most of them exist in the form of defects in the cable system, which has serious hidden dangers to the long-term safe operation of the cable. 2. Reasons for the manufacture of cable joints. In the past, high-voltage cable connectors were die-cast, wound, molded, etc. This requires a lot of on-site manufacturing work. In addition, there will inevitably be air gaps and impurities between the insulating tape layers. Due to the limitations of field conditions and manufacturing technology, problems are prone to occur. The cable joint is divided into the cable terminal joint and the cable intermediate joint. No matter what the joint form, the cable joint failure generally occurs at the insulation shield of the cable, because this is the place where the electrical stress is concentrated. The causes of cable joint failure caused by manufacturing reasons include insulation packing problems, manufacturing defects of stress cone body, oil leakage of sealing ring, etc. 3. Cable grounding system. The cable grounding system includes cable grounding box, cable cross-connection box, cable grounding protection box, protective layer protector, etc. General common problems are mainly poor sealing of the box, water caused by multi-point grounding, resulting in excessive induction current of the metal sheath. In addition, the parameter selection of the protective layer protector is unreasonable or the quality of the zinc oxide crystal is unstable, which can easily lead to the damage of the protective layer protector.

High-voltage cable manufacturers design reasons: thermal expansion caused by cable extrusion lead to breakdown, when the cross-linked cable load is high, the temperature of the cable core rises, the cable thermal expansion. At the corner of the tunnel, the cable is supported on the vertical plane of the bracket, and the crawling force of the long-term heavy-duty cable is very large, which leads to the collapse of the outer sheath and the metal sheath of the bracket, and squeezing into the cable insulation layer, resulting in cable breakdown.

TAG:

Recommend

Service Hotline:

E-mail:

Address:

Yincun Economic Development Zone, Renqiu City, Cangzhou City, Hebei Province