High-voltage cable manufacturers explain the reasons and methods of high-voltage cable grounding

Release time:

2022-12-30

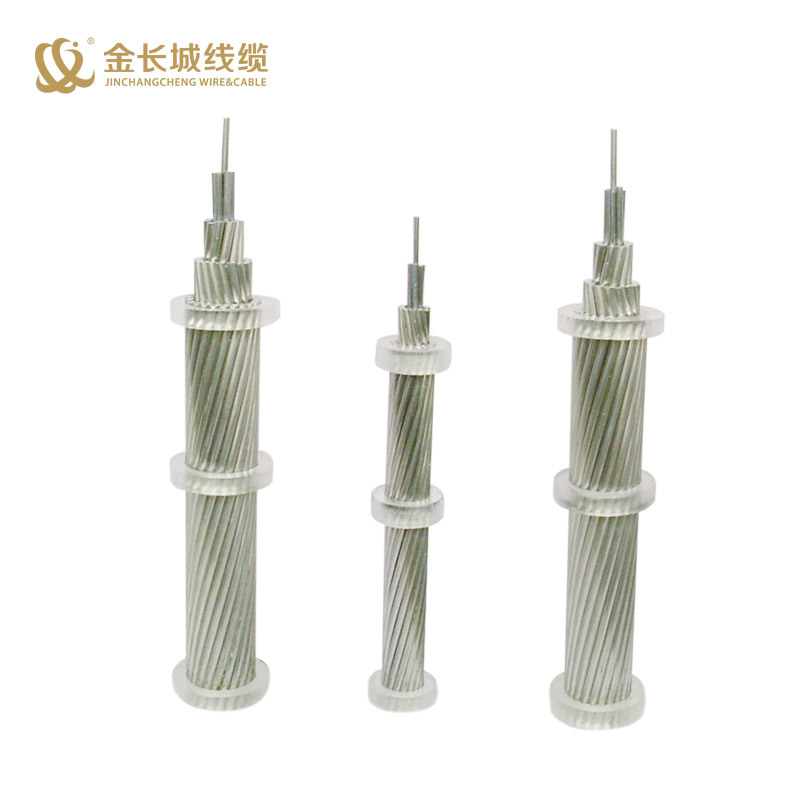

High-voltage cables are used to transmit power between 1kV and 1000kV, and are mostly used for transmission and distribution. The components of a high-voltage cable include, from the inside to the outside: conductor, inner sheath, insulation, filler and outer insulation. Of course, armored high-voltage cables can resist high-strength ground pressure, high-voltage cable manufacturers will be used for underground burial, to prevent other external damage.

High-voltage cables are used to transmit power between 1kV and 1000kV, and are mostly used for transmission and distribution. The components of a high-voltage cable include, from the inside to the outside: conductor, inner sheath, insulation, filler and outer insulation. Of course, armored high-voltage cables can resist high-strength ground pressure, high-voltage cable manufacturers will be used for underground burial, to prevent other external damage.

1, high-voltage three-core cable grounding: 35kV and below the voltage level of the cable at both ends of the ground, this is because most of these cables are three-core cables. During normal operation, the sum of the currents flowing through the three cores is zero, there is basically no induced voltage at both ends of the aluminum clad layer or the metal shielding layer, and there is basically no magnetic chain outside the aluminum clad layer or the metal shielding layer, so there is no induced current flowing through the aluminum clad layer or the metal shielding layer after both ends are grounded. 2. High-voltage single-core cable grounding: When the cable is running with load, an induced voltage will be formed in the shielding layer. If the shielding layer at both ends is grounded at the same time, a loop will be formed between the shielding layer and the earth, which will generate induced current and consume a lot of power, which will cause the cable shielding layer to heat up and affect the normal operation of the line. When the cable line suffers from short-circuit fault, lightning impulse or operating overvoltage, the shielding will form a high induced voltage, which may break down the outer sheath of the cable and endanger personal safety. In order to avoid this phenomenon, high-voltage cable manufacturers usually use one end of the ground. When the line is very long, neutral grounding and cross interconnection can also be used.

Several grounding methods of high-voltage cables: 1. Direct grounding at both ends: This grounding method can reduce the workload, but there is circulation on the metal sheath, and the applicable conditions are harsh. The cable is short, the transmission power is small, and the transmission power has a lot of margin. In this case, there is no need to install a cable sheath protector, which can reduce the workload of operation and maintenance, but there is circulation on the metal sheath, and high-voltage cable manufacturers do not recommend this method. 2. One end of the metal shield is directly grounded, and the other end is protected by the sheath: when the cable is short, one end of the metal sheath is generally directly grounded, and the other end is protected by the sheath. Grounding insulation does not form a loop, which can reduce and eliminate circulation, which is beneficial to improve the transmission capacity of the cable and the safe operation of the cable. According to the specification requirements, the induced voltage on a section of metal sheath that is not directly grounded shall not exceed 50v. If it is connected to an overhead line, the direct grounding is generally installed on the overhead line. 3. Cross interconnection grounding: When the cable line is very long, the high-voltage cable manufacturer recommends that the metal sheath of the cable can be installed through the cross interconnection. Cross connection is to divide the cable into three sections of equal length, and install insulated joints between each section. The metal sheath is led out from the coaxial cable at the insulating joint. After being cross-connected through the interconnection box, the metal sheath is grounded through the cable sheath protector, and the metal sheath at both ends of the cable is directly grounded to form an interconnection section. If the cable wires are long, a multi-segment interconnection can be formed by connecting several interconnected segments.

TAG:

Recommend

Service Hotline:

E-mail:

Address:

Yincun Economic Development Zone, Renqiu City, Cangzhou City, Hebei Province