High-voltage cable manufacturers on the difference between high-voltage cables and low-voltage cables

Release time:

2023-01-09

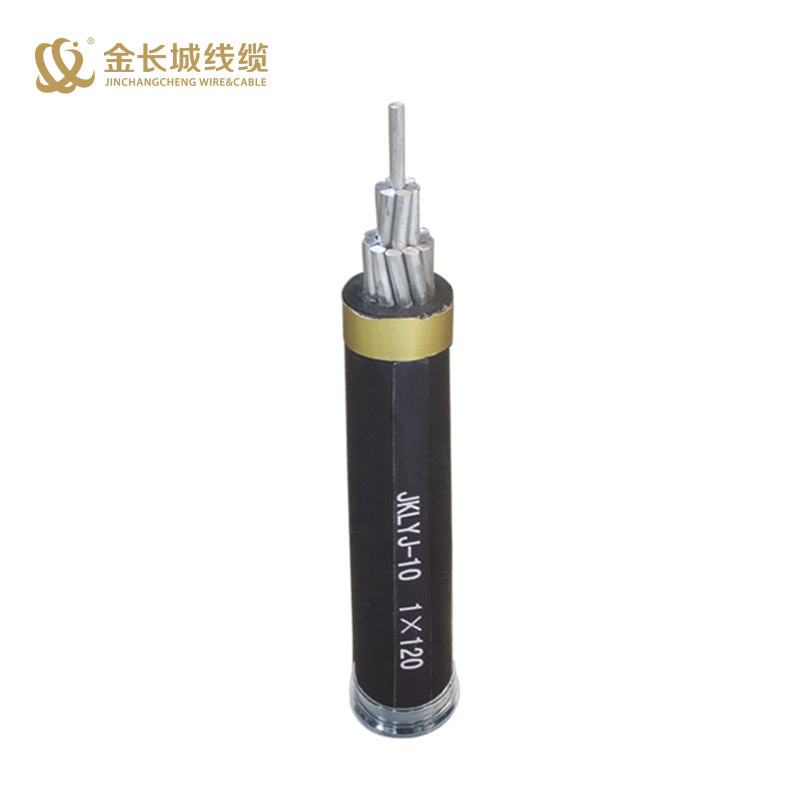

High-voltage cables are used to transmit power between 1kV and 1000kV, and are mostly used for transmission and distribution. The components of a high-voltage cable include, from the inside to the outside: conductor, inner sheath, insulation, filler and outer insulation. Of course, armored high-voltage cables can resist high-strength pressure on the ground. High-voltage cable manufacturers use them for underground burial to prevent other external forces from damaging high-voltage cables and low-voltage cables.

High-voltage cables are used to transmit power between 1kV and 1000kV, and are mostly used for transmission and distribution. The components of a high-voltage cable include, from the inside to the outside: conductor, inner sheath, insulation, filler and outer insulation. Of course, armored high-voltage cables can resist high-strength pressure on the ground. High-voltage cable manufacturers use them for underground burial to prevent other external forces from damaging high-voltage cables and low-voltage cables. There is a big difference between high-voltage cables and low-voltage cables, which are mainly reflected in the following aspects:

1. voltage levels are different: according to the provisions of the high-voltage cable manufacturer, the voltage below 1KV (including 1KV) is defined as low voltage, and 1KV-330KV is called high voltage. Therefore, the rated voltage of 1KV and below is called low-voltage cable, the rated voltage of 1KV-330KV is high-voltage cable, 0.4KV and 10KV voltage level cable is more common in our work and life.

2. structural differences: 1. High-voltage cables:(1) Stranded copper conductors: conductors for transmitting electrical energy, which are made of multiple hard wires. (2) Conductor shielding layer: Since the conductor is twisted by multiple hard wires, there are gaps on the surface, which will cause uneven electric field and partial discharge. Therefore, conductive non-metallic soft materials are filled to ensure adhesion with the insulating layer to uniform electric field and extend the service life of the cable. (3) Insulation layer: Since the electrical gap between the 10KV bare wires is 125mm, the gap between the two wires in the cable is very small, so it is necessary to use better performance cross-linked polyethylene (XLPE) material, which mainly plays an insulating role. (4) Insulation shielding layer: Similarly, when the insulation layer is directly combined with the outer sheath, there will be gaps, so high-voltage cable manufacturers add a conductive semiconductor layer to the insulation layer to uniform electric field and prevent partial discharge. (5) Metal shielding layer: In order to ensure that the semiconductor layer can be reliably grounded, a layer of metal shielding layer is wrapped outside. During normal operation, the metal shielding layer can be directly grounded to discharge the distributed capacitive current between the cable and other conductors, and can shield some electromagnetic interference to prevent interference to other equipment. (6) Filling material: In order to eliminate the mutual inductance between three-phase cables, high-voltage cable manufacturers need to arrange the three-phase cables into a symmetrical shape, and the internal vacancies need to be filled with materials to ensure the stability of the core and the mechanical strength of the cable. (7) Steel tape armor layer: Armored cables are used to increase the mechanical strength of the cable and improve the anti-erosion ability. They are designed for areas that are susceptible to mechanical damage and erosion. 2. Low-voltage cables: The structure of low-voltage cables is different from that of high-voltage cables on the conductor shielding layer, insulation shielding layer, and metal shielding layer. The difference is mainly caused by the different insulation capabilities of different voltage levels. The electric field capability of low voltage 0.4KV is much weaker than 10KV, such as air breakdown or insulation breakdown.

The difference between the 3. methods of use: high-voltage cables can only be used after high-voltage cable manufacturers make cable heads in accordance with strict manufacturing processes, while low-voltage cables do not need to make cable heads. The laying requirements of high-voltage cables and low-voltage cables are also different. In short, the difference between high and low voltage cables lies in the difference in voltage and insulation capacity, and these differences are all to ensure the safety of electricity!

TAG:

Recommend

Service Hotline:

E-mail:

Address:

Yincun Economic Development Zone, Renqiu City, Cangzhou City, Hebei Province