Installation of High Voltage Cable

Release time:

2021-11-16

When installing 6kV or 10kV electrical equipment, we will encounter situations where a single-core short cable is required as a connecting line. In electrical engineering installations, three-core high-voltage cables are sometimes used. Strip the outer skin, strip the ladle armor, and use the three-core wire as a single-core cable. Even if the insulation resistance of the single-core cable meets the requirements, if the core is installed close to the external metal parts, the discharge of structural parts will occur, especially in the wet weather in spring, which will endanger the safety of equipment and personnel.

When installing 6kV or 10kV electrical equipment, we will encounter situations where a single-core short cable is required as a connecting line. In electrical engineering installations, three cores are sometimes usedHigh voltage cable. Strip the outer skin, strip the ladle armor, and use the three-core wire as a single-core cable. Even if the insulation resistance of the single-core cable meets the requirements, if the core is installed close to the external metal parts, the discharge of structural parts will occur, especially in the wet weather in spring, which will endanger the safety of equipment and personnel.

From the electromagnetic field theory, we can see:

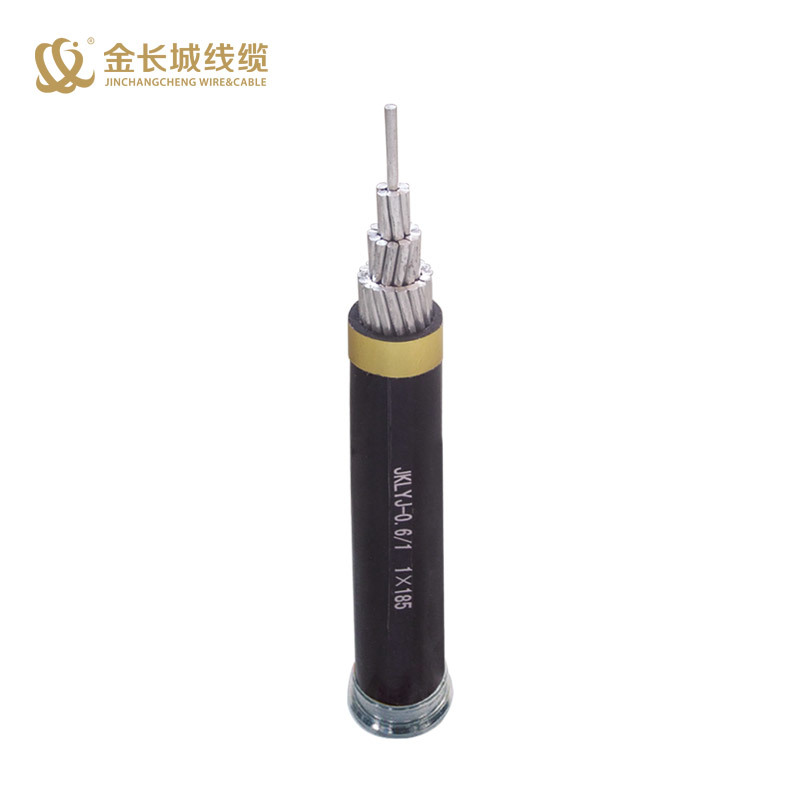

The distributed capacitance of the three-core cable is three-phase balanced and surrounded by a grounded shielding layer. There is no external electric field, only internal electric field, so energy transfer can only be carried out internally without leakage. The distributed capacitance of unshielded high-voltage insulated wire is complex, but the grounding body close to the wire has the largest capacitance and is most likely to produce discharge. Therefore, generally speaking, there will be inner and outer peninsula shielding layers in single-core cables to ensure the safety of the cables in use. Because high-voltage cables are very dangerous during installation, we combine physical knowledge to reduce the risk index of high-voltage cables during installation. Reduce the risk index and improve the quality of high-voltage cables.

Installation of Cable Splice

Domestic construction units generally do not pay much attention to the environmental humidity and dust at the joints. In fact, moisture and small impurities are very harmful to the long-term operation of the cable, which can easily lead to water trees and partial discharges. Therefore, the joint construction must pay attention to environmental humidity and dust. Before construction, attention should be paid to clean up the environment. In summer, joint construction personnel should wear gloves. If the ambient humidity is too high, dehumidification treatment should be carried out (increase the ambient temperature or use a dehumidifier), and the insulating surface should be dried with a blower before inserting the stress cone. The cable shall be heated and straightened before the cable joint. Sometimes, builders think the cable can be heated without bending. In fact, this view is incorrect. There are two reasons why the cable should be heated and straightened: one is to eliminate the mechanical stress in the cable due to distortion during cable laying; the other is to eliminate the dimensional change caused by insulation thermal shrinkage after the cable is put into operation. Therefore, the cable must be heated and straightened before the cable joint.

End treatment of insulation shield

Insulation end treatment is an important step in the work of cable joints. This step has the highest technical and technological requirements, must not be sloppy. If the process is not well mastered, it is easy to grind pits, steps or semiconductor tips at the end of the insulating shield, which is very dangerous.

Stress Cone Dimensional Location

Generally, the method of positioning at both ends is adopted: before the stress cone of the sheath, mark the semiconductor layer at both ends of the cable at an equal distance in a suitable position. When the stress cone sheath reaches the final position, the distance between the two ends and the two ends is required to be approximately the same. This method has high precision and small error.

TAG:

Recommend

Service Hotline:

E-mail:

Address:

Yincun Economic Development Zone, Renqiu City, Cangzhou City, Hebei Province